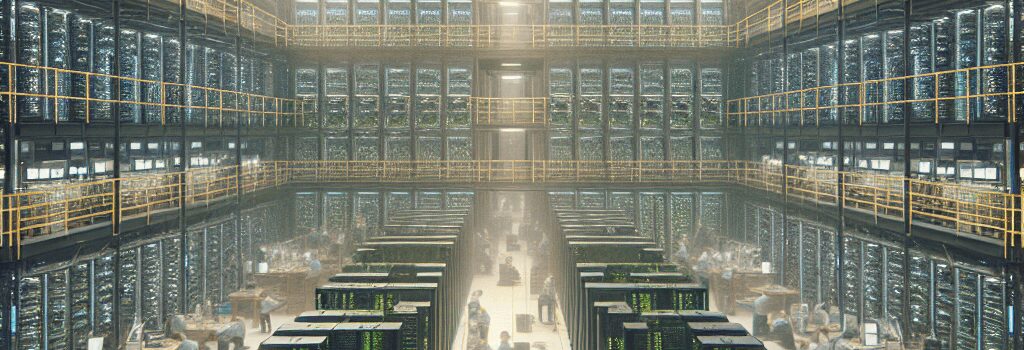

Inside SK TES’s Fredericksburg ITAD Site for Hyperscale Hardware

Hyperscale data centers generate enormous volumes of retired hardware every year. At SK TES’s 128,000-square-foot IT asset disposition (ITAD) facility in Fredericksburg, Virginia, each server, drive, and memory module undergoes rigorous data sanitization, inventory tracking, and disposition—to be securely wiped, repurposed, or shredded. This visit reveals the technical backbone, compliance regimes, and emerging automation trends shaping the ITAD sub-industry.

Facility Overview and Workflow

Located in the heart of Northern Virginia’s “Data Center Alley,” the SK TES site handles inbound equipment from the region’s hyperscale giants, enterprise fleets, and government agencies. Compliance with NIST SP 800-88 Rev. 1 guidelines and Department of Defense

standards (DoD 5220.22-M) form the foundation of their data destruction protocols.

- Receiving & Inspection: Pallets arrive with tamper-evident seals. Each unit—servers, laptops, switches—is tagged with a unique barcode and RFID asset tag.

- Data Discovery: Technicians log BIOS, SMART, and firmware details. Hidden media (USB, SD, M.2) are detected via X-ray and manual inspection.

- Sanitization: Drives are cryptographically erased (ATA Secure Erase, NVMe Enhanced Secure Erase), or overwritten with multi-pass patterns when required by clients.

- Grading & Testing: Devices receive a three-character grading code (functional/ cosmetic/value). Memory modules pass through automated handlers like the RoboFlex II.

- Disposition Paths: Items clear for resale go to retail or wholesale channels; non-compliant gear is shredded on-site or sent to R2/ e-Stewards certified recyclers.

Undocumented Drives: The Tiny Terror

Kent Green, site manager, emphasizes that “undocumented storage is our biggest risk.” In practice, this means hidden SATA, USB, or M.2 sticks installed by overzealous IT staff or end users. To combat this:

- High-resolution X-ray scanners pinpoint unregistered media.

- Customized scripts enumerate storage controllers via SSH (e.g.,

lsscsiandsmartctlon Linux switches). - Firmware-level wiping tools (Blancco, WhiteCanyon) guarantee 100% bit-level erase.

“Many managers are surprised when they see the extra drives we uncover,” Green says. “Complete traceability is non-negotiable.”

Component Harvesting and Full-Body Laptop Skins

After sanitization, devices are reassembled and tested. Laptops that meet retail criteria undergo:

- Automated keypress diagnostics to verify each keyboard row.

- Battery health checks targeting ≥80% residual capacity.

- Physical refresh: proprietary full-body adhesive skins restore cosmetics and conceal scratches—custom-cut for Lenovo T-series, Dell Latitude, and HP EliteBook models.

Laptops entering the retail channel receive UN3481 batteries-inside labeling and are sold under SK TES’s “Stock Must Go” brand on eBay and partner marketplaces.

Massive Parallel Drive Sanitization

The site houses 29 automated wiping bays, each capable of handling up to 192 SATA and SAS hard disks. At full capacity, 5,632 drives can be erased concurrently. Using tailored DoD 7-pass and NSA patterns, monthly throughput reaches upwards of 100,000 drives—double last year’s volume.

Solid-state devices receive scoping per the latest NIST SP 800-88r1 guidelines: secure erase commands are issued at the firmware layer, followed by verification reads. Drives failing verification are funneled to physical destruction.

Regulatory Compliance and Industry Standards

ITAD providers operate at the nexus of data security, environmental law, and corporate governance. Key compliance frameworks include:

- NIST SP 800-88 Rev. 1: Media sanitization guidelines endorsed by the U.S. government.

- ISO 27001: Information security management systems for data protection.

- R2 & e-Stewards: Responsible recycling certifications ensuring minimal environmental impact.

Recent news—per the Financial Times—highlights AWS and Microsoft adopting 100% data shredding policies, with Google following suit. The European Union’s Circular Electronics Initiative, enforced in 2024, now mandates manufacturers to offer device take-back programs with secure erasure capabilities.

Environmental Impact and Sustainability Metrics

While data security is paramount, the sustainability angle drives growing reuse rates. According to an U.S. National Renewable Energy Laboratory study, ~50 million end-of-life drives will be shredded annually by 2025, emitting approximately 60,000 metric tons of CO₂e if fully recycled. ITAD firms like SK TES offset this by:

- Refurbishing ~70% of incoming devices, extending useful life by 3–5 years.

- Reclaiming 98% of precious metals from shredding outputs (gold, palladium, copper).

- Partnering with regional recyclers to ensure >95% diversion from landfills.

Emerging Trends in ITAD Automation

Automation and AI are accelerating ITAD workflows. SK TES is piloting:

- Robotic disassembly cells using machine vision to sort PCBs and chassis parts.

- AI-driven defect classification models that analyze thermal-imaging scans for PCB hot spots.

- Blockchain-based asset tracking for immutable audit trails and real-time client dashboards.

Gartner forecasts ITAD market growth at 12% CAGR through 2027, driven by data sovereignty regulations and corporate ESG targets. IDC projects that by 2026, over 30% of large enterprises will deploy on-premises secure erase appliances, complementing outsourced ITAD services.

Conclusion

SK TES’s Fredericksburg site illustrates the technical sophistication and regulatory rigor required to retire hyperscale hardware securely. From hidden drive discovery to multi-pass sanitization, component harvesting, and sustainable recycling, ITAD has evolved into a critical sub-industry supporting both data privacy and circular economy goals. As data center footprints grow, so too will the demand for advanced ITAD services that blend stringent security with responsible environmental stewardship.