NASA SLS Booster Test Faces Nozzle Catastrophe Amid Uncertainty

Program Overview

The Space Launch System (SLS) remains at the heart of NASA’s Artemis program, designed to return humans to the Moon and pave the way for Mars missions. Originally envisioned to leverage surplus Space Shuttle hardware, SLS has evolved into a bespoke heavy-lift launcher with:

- Core stage powered by four RS-25 engines producing a combined 2 million pounds of thrust, fueled by liquid hydrogen and liquid oxygen.

- Dual Solid Rocket Boosters (SRBs) each delivering up to 3.6 million pounds of thrust at liftoff.

- Interim Cryogenic Propulsion Stage (ICPS) for trans-lunar injection on Artemis I–V.

Despite three successful flights planned under current appropriation, NASA and the White House are at odds over funding levels beyond Artemis V. The Trump administration proposed termination after Artemis III to favor commercial heavy-lifters, while the Senate’s draft appropriations bill extends SLS through Artemis V.

RS-25 Engine Production Restart

After a decade-long hiatus since the end of the Space Shuttle era, L3Harris (formerly Aerojet Rocketdyne) restarted RS-25 production under a 2015 contract. Key milestones:

- 2015: Contract awarded to reestablish RS-25 tooling and supply chain.

- 2020: Additional 18 engines ordered at ~$100 million each, targeting cost reduction to $70 million.

- June 2025: First flight-worthy RS-25 (#20001) passed a 500-second acceptance test at Stennis Space Center, throttling to 111% rated thrust.

“We’ve replicated the RS-25’s performance with modern manufacturing techniques and upgraded components,”

said Kristin Houston, President of Space Propulsion & Power Systems at L3Harris. Advanced features include a redesigned pogo accumulator and an improved main combustion chamber liner with additive-manufactured cooling channels.

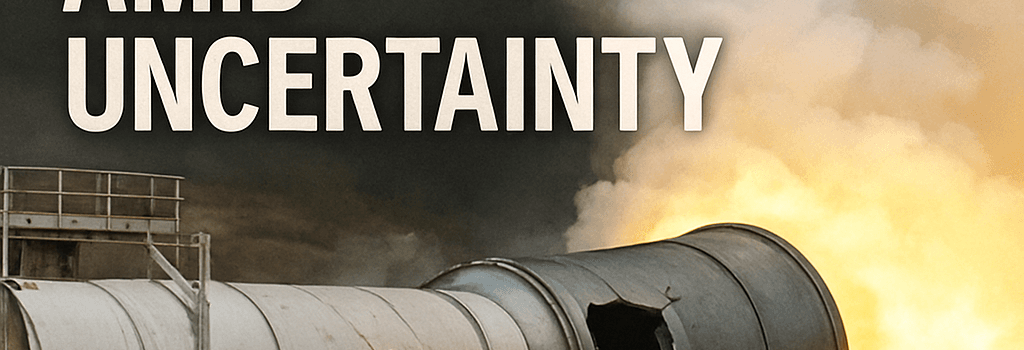

BOLE Booster Test Failure

On June 26, 2025, Northrop Grumman and NASA conducted the first ground test of the Booster Obsolescence and Life Extension (BOLE) motor at Promontory, Utah. This segmented solid rocket motor is slated for Artemis IX and beyond, featuring:

- Carbon-fiber composite cases replacing steel, reducing mass by ~20% and increasing burst pressure margins.

- Electronic Thrust Vector Control (eTVC) replacing hydraulic actuators for finer steering response.

- Proprietary high-energy composite propellant, delivering ~3% higher specific impulse than shuttle-era PBAN grains.

At T+100 seconds, a hot plume breached the aft joint, resulting in nozzle disintegration. Debris struck the test stand, and residual burning ignited brush fires in adjacent hills. The motor continued firing uncontrolled until propellant exhaustion at T+130 seconds.

Technical Deep Dive: Materials & Propulsion

The BOLE nozzle uses an advanced phenolic-impregnated carbon ablator (PICA) liner bonded to a carbon-fiber-reinforced polymer (CFRP) exit cone. Finite-element analysis indicates thermal gradients in the aft throat region can exceed 2,000 K, demanding precise layup tolerances. NASA and Northrop engineers are investigating:

- Joint seal integrity under high-frequency pressure oscillations.

- Microcracking in composite layers due to thermal shock.

- Potential redesign of the aft closure ring and insulation blanket.

Programmatic Implications & Commercial Alternatives

With uncertainties in SLS’s long-term funding, NASA is evaluating commercial heavy-lift options as contingency plans:

- SpaceX Starship: Fully reusable vehicle with planned ≥150 tonne LEO capacity, multiple hop tests in 2025.

- ULA Vulcan Centaur with BE-4 boosters: Hot-fire tests for BE-4 continue at NG’s Mississippi facility.

- Blue Origin’s New Glenn: Methane-fueled, 45 tonne LEO capacity, targeted first flight in late 2025.

NASA’s 2026 budget request includes $450 million for commercial lunar lander and launch services, signaling a shift toward public–private partnerships.

Additional Analysis: Cost, Schedule & Risk

Each Artemis SLS flight carries a notional price tag of $4.2 billion. When spread over four flights, production cost per RS-25 is ~$85 million, yet Starship’s marginal cost could be under $50 million per flight. Key risk factors:

- Supply chain fragility for high-grade Niobium alloys in RS-25 turbopumps.

- Testing resource bottlenecks at Stennis and Promontory stands.

- Political volatility impacting multi-year funding.

Future Prospects & Budget Considerations

Congressional hearings in July 2025 will determine Artemis beyond V. NASA Administrator Bill Nelson has advocated for a five-flight baseline, while the Office of Management and Budget pressures for early termination. A compromise may emerge: extend SLS through Artemis VII while ramping up Starship certification.

Expert Perspectives

“SLS provides critical early lunar capabilities, but long term we need a mixed fleet,”

noted Dr. Emily Carney, former NASA Lunar Architecture lead.

“Combining SLS reliability with reusable systems can optimize cost and cadence for sustained lunar presence.”

As NASA digests the BOLE test anomaly and awaits the next RS-25 engine delivery, the agency stands at a crossroads: continue legacy expendables or pivot to commercial reusables. The coming months will shape the trajectory of U.S. deep-space exploration for decades.